Detail produk:

Syarat-syarat pembayaran & pengiriman:

|

| Mengalir: | 5-500m3 / jam | Kepala: | 10-70 m |

|---|---|---|---|

| Suhu Operasional: | -20 ° C hingga + 120 ° C | Batang: | Poros panjang |

| Konten Padatan: | Max. Maks. allowable up to 5% diizinkan hingga 5% | Struktur: | Vertikal |

| Fitur: | Ketahanan Korosi Yang Tinggi | ||

| Cahaya Tinggi: | vertical submersible centrifugal pumps,vertical long shaft pump |

||

Volume Tinggi Sangat Efisien Vertikal Submersible Dewatering Pumps Immersion Pumps

Apa itu Pompa Celup?

A submersible pump, like any other pump, is used to move liquids from one point to another. Pompa submersible, seperti pompa lainnya, digunakan untuk memindahkan cairan dari satu titik ke titik lainnya. We can divide submersible pump two semi-submersible pump and total submersible pump. Kita dapat membagi dua pompa semi submersible dan dua pompa submersible. The major difference between a submersible pump and any other type is that it is installed completely submerged in the liquid that it is required to pump. Perbedaan utama antara pompa submersible dan jenis lainnya adalah pompa terpasang sepenuhnya dalam cairan yang harus dipompa. This type of pump has a hermetically sealed motor which is close-coupled to the pump body. Jenis pompa ini memiliki motor yang tertutup rapat yang terhubung erat dengan badan pompa.

Aplikasi

1) Sampaikan media cair korosif dan abrasif (kadar padatan tidak lebih dari 15%).

2) Dalam industri kimia, metalurgi, industri listrik, industri pembuatan kertas, industri makanan, industri farmasi dan industri serat sintetis

Keuntungan

Priming: They don't have to be primed. Priming: Mereka tidak harus dipersiapkan. They are self-priming because they operate below the surface of the fluid being pumped. Mereka priming diri karena mereka beroperasi di bawah permukaan cairan yang dipompa.

Efficiency: A submersible pump has the head pressure of liquid on the suction end to help it operate. Efisiensi: Pompa submersible memiliki tekanan kepala cairan di ujung hisap untuk membantunya beroperasi. It doesn't need to use as much energy in drawing liquid into the pump and is, therefore, more efficient. Tidak perlu menggunakan banyak energi dalam menarik cairan ke dalam pompa dan, karenanya, lebih efisien.

Corrosion: Submersible pumps are often used to handle corrosive and abrasive liquids. Korosi: Pompa submersible sering digunakan untuk menangani cairan korosif dan abrasif. Seals are especially prone to corrosion, which leads to leaks and damage to the motor. Seal sangat rentan terhadap korosi, yang menyebabkan kebocoran dan kerusakan pada motor. To counteract corrosion these pumps need to be made of corrosion-resistant material. Untuk menangkal korosi, pompa ini harus dibuat dari bahan yang tahan korosi.

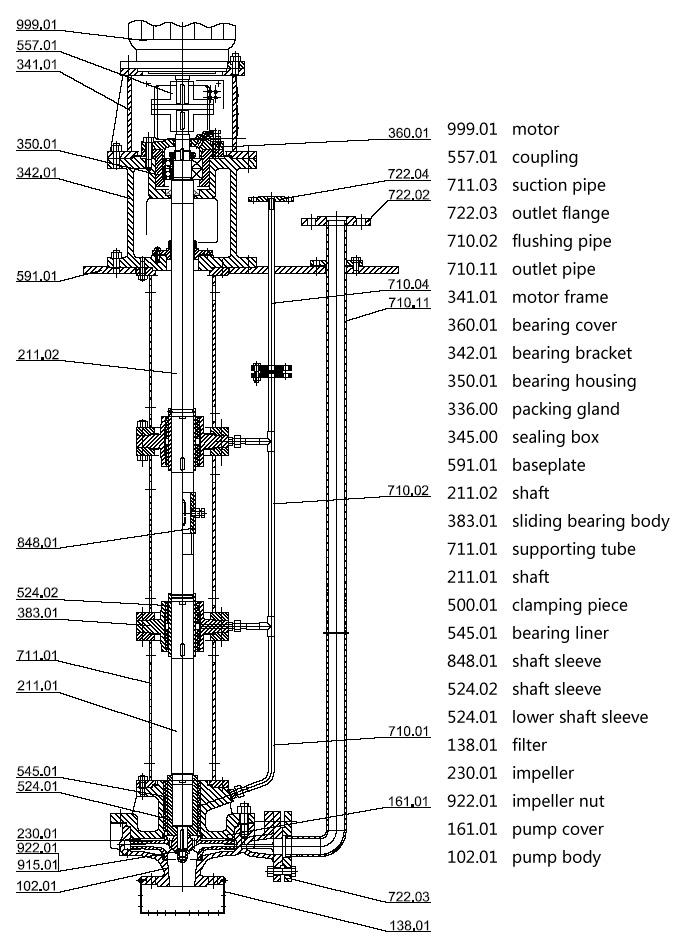

Struktur

Bahan

| Bagian pompa | Bahan |

| Casing pompa | Besi cor tahan asam atau baja tahan karat khusus |

| Impeller dan pakai cincin | Baja tahan karat khusus |

| Bantalan lengan | Ferro-silicium atau paduan khusus |

| Batang |

Duplex stainless steel dengan lapisan FEP |

Parameter Teknis

|

Model |

putar kecepatan n = 2950r / mnt |

putar kecepatan n = 1475r / mnt |

||||||

|

Aliran (m3 / jam) |

Head (m) |

ρ = 1 |

ρ = 1.35 |

Mengalir (m3 / jam) |

Kepala |

ρ = 1 |

ρ = 1.35 |

|

|

Tenaga motor |

Tenaga motor |

|||||||

|

ZAL25-200 |

7.5-11.5 |

28-49 |

2.2-5.5 |

3-7.5 |

4-5.8 |

6.5-12 |

0.75-1.1 |

0.75-1.1 |

|

ZAL25-250 |

10.8-12.5 |

46-78 |

5.5-11 |

7.5-15 |

5.4-6.3 |

11.5-19.5 |

1.1-1.5 |

1.5-2.2 |

|

ZAL25-315 |

15.3-20 |

74-130 |

15-30 |

22-37 |

7.6-10 |

18.5-32 |

2.2-3 |

2.2-4 |

|

ZAL40-160 |

20-28 |

16-33 |

2.2-5.5 |

3-7.5 |

9.5-14 |

4.5-8 |

0.75-1.1 |

0.75-1.1 |

|

ZAL40-200 |

18-29 |

20-53 |

4-11 |

5.5-15 |

9.5-14.5 |

7-13 |

1.1-1.5 |

1.1-2.2 |

|

ZAL40-250 |

21-32 |

47-78 |

7.5-18.5 |

11-22 |

10.5-16 |

11-19.5 |

1.1-3 |

1.5-4 |

|

ZAL40-315 |

29-42 |

61-115 |

15-37 |

22-45 |

15-21 |

15-29 |

3-5.5 |

4-7.5 |

|

ZAL50-160 |

31-50 |

17-34 |

3-11 |

4-15 |

16.5-25 |

4-8.4 |

0,75-1,5 |

1.1-2.2 |

|

ZAL50-200 |

43-62 |

28-82 |

7.5-18.5 |

11-22 |

22-31 |

7-13 |

1.1-3 |

1.5-3 |

|

ZAL50-250 |

50-70 |

45-82 |

15-30 |

18.5-37 |

26-35 |

11-20 |

2.2-4 |

3-5.5 |

|

ZAL50-315 |

57-87 |

57-115 |

22-55 |

30-75 |

30-44 |

14-28 |

3-11 |

4-11 |

|

ZAL50-400 |

60-82 |

102-194 |

45-110 |

75-160 |

30-41 |

25-48 |

7.5-15 |

11-22 |

|

ZAL80-160 |

66-94 |

17-32 |

5.5-15 |

7.5-18.5 |

34-47 |

4-8 |

1.1-2.2 |

1.1-3 |

|

ZAL80-200 |

70-103 |

30-54 |

11-30 |

15-37 |

36-51 |

7.5-12.5 |

1.5-4 |

2.2-5.5 |

|

ZAL80-250 |

87-127 |

45-82 |

22-45 |

30-75 |

46-64 |

11-20 |

3-7.5 |

4-11 |

|

ZAL40-315 |

90-141 |

74-127 |

37-90 |

45-132 |

45-70 |

18-33 |

5.5-15 |

7.5-18.5 |

|

ZAL80-400 |

116-171 |

95-187 |

75-160 |

90-220 |

53-85 |

25-46 |

11-22 |

15-30 |

|

ZAL100-160 |

110-162 |

12-29 |

7.5-22 |

11-30 |

55-81 |

3-7.2 |

1.1-3 |

1.5-4 |

|

ZAL100-200 |

135-193 |

26-50 |

18.5-45 |

30-55 |

70-95 |

6-12.5 |

3-5.5 |

3-7.5 |

|

ZAL100-250 |

170-230 |

44-79 |

37-75 |

45-90 |

90-115 |

10-20 |

5.5-11 |

7.5-15 |

|

ZAL100-315 |

170-250 |

71-126 |

75-132 |

75-200 |

86-125 |

17.5-31 |

11-18.5 |

11-30 |

|

ZAL100-400 |

224-300 |

105-194 |

110-250 |

160-355 |

115-150 |

26-48 |

15-37 |

22-45 |

|

ZAL150-250 |

310-190 |

40-74 |

55-110 |

75-160 |

155-195 |

10-18.5 |

11-15 |

11-22 |

|

ZAL150-315 |

310-442 |

68-125 |

90-250 |

132-355 |

150-220 |

17-32.5 |

15-30 |

18.5-45 |

|

ZAL150-400 |

400-520 |

113-502 |

200-400 |

280-500 |

200-260 |

28-51 |

30-55 |

37-75 |

|

ZAL150-500 |

|

|

|

|

208-300 |

45-77 |

45-110 |

75-132 |

|

ZAL150-630 |

|

|

|

|

220-360 |

60-115 |

75-200 |

110-250 |

|

ZAL200-250 |

470-610 |

32-72 |

75-160 |

90-220 |

240-305 |

8-17.5 |

11-22 |

15-30 |

|

ZAL200-315 |

480-710 |

65-122 |

132-355 |

185-450 |

350-350 |

15-30 |

18.5-45 |

22-55 |

|

ZAL200-500 |

|

|

|

|

330-495 |

48-84 |

75-185 |

90-220 |

|

ZAL200-560 |

|

|

|

|

350-540 |

62-105 |

110-250 |

132-355 |

|

ZAL200-630 |

|

|

|

|

372-580 |

75-132 |

132-315 |

185-450 |

|

ZAL250-315 |

|

|

|

|

424-545 |

13-27 |

30-55 |

37-75 |

|

ZAL250-400 |

|

|

|

|

500-660 |

24-49 |

53-132 |

75-160 |

|

ZAL250-500 |

|

|

|

|

630-800 |

42-82 |

110-280 |

160-400 |

|

ZAL250-560 |

|

|

|

|

665-860 |

57-106 |

160-400 |

250-560 |

|

ZAL300-400 |

|

|

|

|

780-1050 |

26-48 |

90-200 |

132-280 |

|

ZAL300-500 |

|

|

|

|

870-1240 |

42-78 |

160-450 |

250-560 |

|

ZAL300-560 |

|

|

|

|

950-1340 |

56-104 |

280-560 |

400-800 |

|

ZAL300-630 |

|

|

|

|

950-1450 |

75-132 |

355-1000 |

500-1400 |

|

ZAL300-500 |

|

|

|

|

1300-1870 |

38-74 |

220-630 |

315-1000 |

|

ZAL300-560 |

|

|

|

|

1500-2040 |

54-98 |

355-900 |

500-1250 |

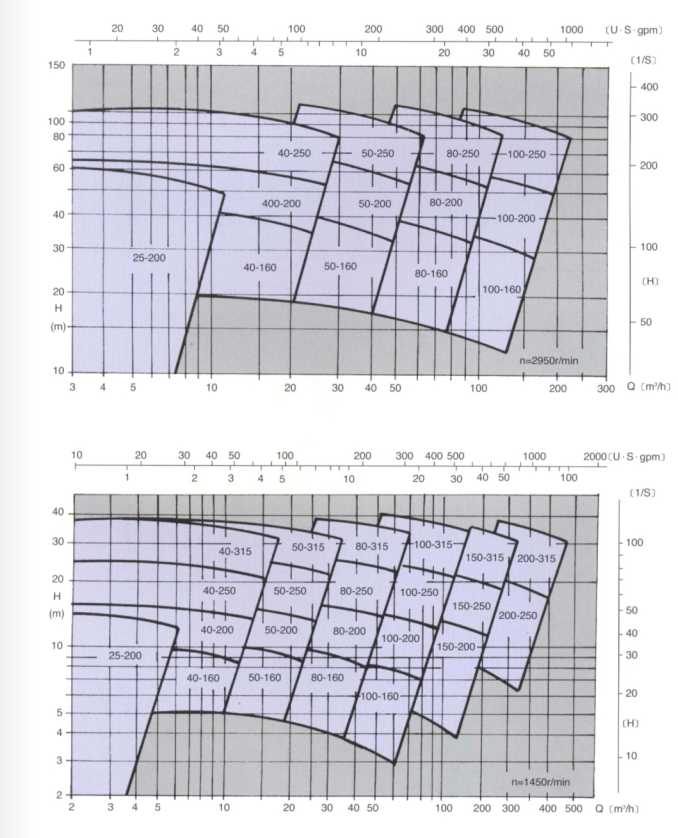

Rentang kinerja

Kontak Person: Cecile

Tel: 0086-19180408652